What two things can frustrate a millennial? Phone calls and Amazon orders that didn’t arrive the next day after being purchased. If the former issue is a gray area of digital influence, the latter one is a real-life catastrophe today.

Due to a massive boom in Internet-of-Things (IoT) solutions in supply chain management, late deliveries and many other roadblocks in logistics are becoming less common. That’s why companies across the entire supply chain intend to adopt IoT technology to streamline their operations. FinancesOnline reports that IoT is a priority technology for 39% of companies, and big players, like DHL and Amazon, are already adopting it at a rapid pace.

It means that your business idea to build your own IoT solution for supply chain management can be profitable. However, you need to know what exactly you’re going to develop since opportunities are colossal. The JatApp team will provide you with several examples of big companies using IoT across different links of the supply chain to inspire you to launch your own IoT project.

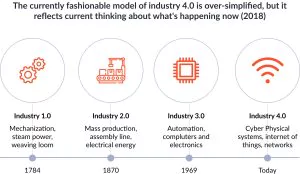

Supply chain 4.0

The role of IoT supply chain management is big today, so the term “supply chain 4.0” has come into common use. But what does it mean?

Supply chain 4.0 is a contemporary supply chain that includes the use of connected devices, artificial intelligence (AI), and data analytics to minimize performance barriers and make the management process more efficient.

Before we start a more detailed discussion, we would like to remind you that the benefits of IoT in the supply chain can be observed within any of its links: raw material provider, manufacturer, distributor, warehouse, and retailer. Large companies already tapped into each of these links, so let’s take a look at the relatable examples.

Raw material

When you think about raw materials in supply chain management, it usually means mining of the natural resources. The use of robotic devices is the most common solution in this case, but raw materials aren’t limited to natural resources only.

In fact, food supply chain management offers an ocean of opportunities. For instance, Golden State Foods, the main meat provider for McDonald’s, partnered with IBM to build IoT solutions for controlling meat quality.

The company uses Radio Frequency Identification (RFID) chips to tag boxes with frozen beef patties to keep track of the food safety and storage conditions. In such a way, Golden State Foods manages to build trust with its partners.

Manufacturer

Speaking about manufacturers’ attempts to harness an uninterrupted production, we need to say that the use of IoT is an effective way to optimize the manufacturing process.

Manufacturing process involves a wide range of activities and different equipment that can break at any moment. Such misfortunes result in production disruptions, as the manufacturer has to stop and fix the problem.

By the use of smart sensors and cameras, observation of the production process gets under the thumb of the manufacturer. As soon as any part of equipment shows signs of unhealthy performance, IoT devices will send an alert notification, and the manufacturer can take preventive action or just get ready to repair the machinery within the shortcoming future.

Aside from forecasting such serious disruptions in production, IoT devices can be simply used to observe the manufacturing process and gather data about production bottlenecks, inefficiencies, quality defects, and resource leaks. At this point, IoT supply chain solutions can be paired with Big Data or AI technology to process the data and predict the consequences for the current approach to production management.

Volvo uses IoT for manufacturing in an unusual, but perhaps the most practical way: the car manufacturer integrates IoT real-time tracking devices in its trucks to optimize remote diagnostics and troubleshooting. Network World reports that this IoT integration reduces Volvo truck diagnostics time by 70% and repair time by 25%. IoT devices don’t observe a production process, but actually participate in it and enable fleet managers to ensure that all Volvo trucks are in a good shape to drive a long way to a client’s warehouse.

Distributor

The main problem that relates to transportation of goods is delays. IoT technology is commonly used to address this problem with RFID tags and other smart devices by tracking a cargo truck in real time. Consequently, all stakeholders involved in the goods delivery process can be informed about the current location of the shipment and get timely notifications about any extraordinary issues that can cause a delivery delay.

Besides, using tracking technology helps to optimize logistic routes to cut delivery costs and reduce the carbon footprint within a supply chain. In addition, scanning of barcodes or RFID chips can be used for reading the parcel contents and instructions about their storage/handling guidelines.

On a side note, storage of goods on the go is as important as at any other point of the supply chain, which is why temperature and humidity control solutions can also be vital IoT technology for goods distributors and logistics companies.

As for large companies making a good use of IoT in this link of supply chain, DHL should be mentioned. The corporation implements IoT solutions across all links of the supply chain, but if we bring the distribution part into a sharp focus, DHL smart shipments are worth describing.

The company uses RFID chips and sensors to track its shipments and report about the current temperature conditions, light availability, truck speed, parcel safety, and so on. As a result, the application of IoT in logistics helps DHL ensure that it doesn’t delay any of its orders, while customers get their parcels in a good condition.

Warehouse

When goods arrive at the warehouse, they still should be stored according to the standards. That is why, the same sensors, scanners, humidity controllers, and smart thermostats are the most common IoT solutions used for controlling the storage conditions.

Moreover, RFID chips and barcode scanners can be good tools for inventory management. In case some of the items are out of stock or running out, businesses will be notified and can plan the stock replenishment accordingly.

Warehouses are usually large storage buildings, where many goods can be present at the same time, which makes finding and picking the necessary item a tough task. RFID tags can be used for mapping goods across the warehouse, while smart glasses and headsets can read the information about the item’s delivery terms, parcel content, storage conditions, and such. By having these devices at hand, warehouse workers can significantly decrease the picking time and avoid goods mishandlings.

But Amazon, as one of the global supply chain giants, advances warehouse management with robotic technology. Yes, you read that correctly, smart robots move across Amazon warehouses and help humans to pick and pack customers’ orders. Apart from reducing operations’ time, robots are more careful than humans, thereby ensuring that Amazon orders aren’t delivered broken into pieces.

Retailer

Finally, when goods reach a retailer, they need to be sold effectively. And IoT technology handles this task as good as in all previous cases we’ve discussed.

With RFID chips and barcode scanners, retailers can track the number of items remaining in stock to plan product replenishment. This solution helps shops, supermarkets, and even small stores keep their stocks full and customers satisfied as they don’t leave a store without a product they wanted to buy.

This kind of IoT solution is exactly what Levi Strauss uses. By putting RFID tags on the products in their outlets, the company is now able to track how many items of each product they have left, when a new arrival can be expected, or where is the nearest Levi’s store that has a desired product in stock.

Needless to say, this solution makes the sales process more effective, while customers won’t have to wait for their favorite Levi’s 501 model (okay, it’s our favorite one). IoT-based technology has boosted supply chain efficiency so strongly that companies have no other choice but to engage in adoption of relatable technologies. Customers won’t wait, even though they came to buy specifically a pair of Levi’s jeans.

Levi’s inventory solution developed by Intel

Bring your idea to life

IoT in supply chain management is flooded with business opportunities today. The examples we’ve covered in this blog post just give an idea of what you can develop to advance supply chain management with IoT technology.

We encourage you to come up with your own vision of IoT in the supply chain management system, while we can provide you with a professional tech team for IoT solutions development. By cooperating with us, you’ll have access to the largest talent pool in Eastern Europe, and cut development costs by up to 60%.

Get in touch with us to share your project idea. We’ll reach out to you as soon as possible.